PV Kit Direct Attachment Solution

The concept of combining photovoltaic arrays with standing seam metal roofing is growing—and for good reasons. A standing seam metal roof has a life expectancy consistent with that of framed PV modules.

A 30-year power source on a 40-year roof, along with zero-penetration technology, creates the most sustainable roof system available with alternative power generation, all without compromising the roof manufacturer’s warranty!

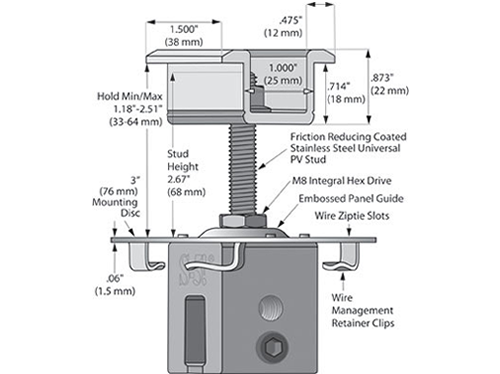

The new stainless steel mounting disk is designed to ensure conductivity with anodized aluminum module frames.

- Listed to the new UL Subject 2703, a standard that covers both bonding and mounting

- ETL Listed to UL 1703

- Groundbreaking new mounting disk: twelve nodes designed to ensure module-to-module conductivity

- Simply anchor the module with the S-5-PV Direct Attachment Solutions (according to the installation instructions) and it automatically provides a ground path within the module frames and through the S-5-PV Direct Attachment Solutions

- No lugs/wire required, except to connect one string of modules to another and to ground the system

- In most cases, this connection detail represents a savings of $6-$12 per unit and is sufficient to pay for the entire S-5-PV Direct Attachment Solutions and clamp setup!

- The stainless steel mounting disk is able to withstand severe conditions and is compatible with the S-5-B Mini for copper roofs.

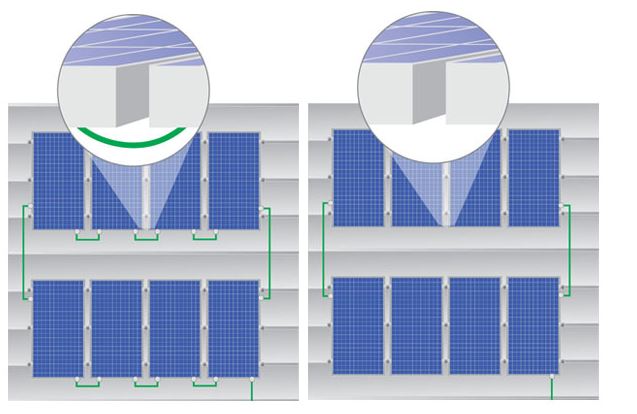

(Left) Without the S-5-PV Direct Attachment Solutions, lugs or copper wires are required to bond PV panels within a string of modules.

(Right) Using the S-5-PV Direct Attachment Solutions, wires and lugs are no longer needed from module-to-module, but will still be needed to bond strings together and to ground the system. Note: The drawings above show an example of continual conductivity; please refer to the engineer for specific job layouts.